U.S. Machine Tool Market. Analysis And Forecast to 2030

Get instant access to more than 2 million reports, dashboards, and datasets on the IndexBox Platform.

View PricingU.S. Machine Tool Market Peaked at $9.7B

Photo: © Wichan sumalee / Bigstockphoto

According to market research conducted by IndexBox, the machine tool market in the U.S. increased by X% in 2016 to X million USD. Previously, an abrupt drop was recorded in 2008, which was then followed by a recovery through to 2012. Afterwards, the market value leveled off, fluctuating mildly from 2013-2016.

The growth in demand for machine tools from the processing industries, which is expected to continue against the background of the general economic and investment activity growth of the United States, the increase in the number of new enterprises, and the modernization of old equipment in existing enterprises, will contribute not only to the growth of the market, but also to the growth of domestic production. Therefore, the U.S. growth in machine tool consumption is expected to accelerate slightly to +X% per year from 2016 to 2025 (currently +X% per year from 2008-2016).

Metal machining centers (multifunction numerically controlled machines) accounted for the highest share (X% in 2016) of U.S machine tool manufacturing, followed by rebuilt metal-cutting machine tools, remanufactured metal-cutting machine tools, and parts for metal-cutting-type machine tools (X%), metal punching and shearing machines (including power and manual) and bending and forming machines (power only) (X%), metal grinding, polishing, buffing, honing, and lapping machines, excluding gear-tooth grinding, lapping, polishing, and buffing machines (X%), metal gear cutting machines (X%) and metal lathes (turning machines) numerically and nonnumerically controlled (X%). The other categories occupy about X% in the aggregate.

The most notable growth rates in U.S machine tool manufacturing from 2008 to 2016 were attained by rebuilt metal-cutting machine tools, remanufactured metal-cutting machine tools, and parts for metal-cutting-type machine tools (+X% per year), while the other leading categories experienced more modest paces of growth.

The U.S. exported X billion USD of machine tool in 2016, which accounted for X% of U.S. machine tool output. There was a mixed trend of exports value: after the decline in 2009, it recovered over the next two years and downturned from 2013 to 2016. This, however, enabled the U.S. to take the fourth spot in global machine tool exports (with an X% share, based on USD), following Japan (X%), Germany (X%) and Italy (X%).

In 2016, the main destinations of U.S. machine tool exports were Mexico (X%), Canada (X%) and China (X%). China had the highest annual average growth rate of imports from the U.S. (+X%) among the leaders from 2007 to 2016. The share exported to Mexico (+X percentage points) and China (+X percentage points) increased, while the share sent to Canada illustrated negative dynamics (-X percentage points). The shares of the other countries remained relatively stable throughout the analyzed period.

Despite fierce competition, the U.S. continues to be one of the most attractive destinations for overseas suppliers, taking the second spot in global machine tool imports (with a X% share, based on USD), following China (X%).

The value of total U.S. machine tool imports totaled X billion USD in 2016, with a declining trend over the last four years. Intense competition from imports, particularly from Japan and Germany, has significantly constrained industry performance during this period. From 2008 to 2016, the import share in total consumption decreased from X% to X% due to rise of the value of the domestic production. As a result, the domestic manufacturers strengthened their market position in 2016, but imports still comprised a major market share.

In 2016, Japanese (X% of the market, in value terms) and German (X%) machine tool held an important share in total U.S. consumption. The share of Japanese machine tool decreased by X percentage points, the share of products from the Republic of Korea decreased by X percentage points, suppliers from Germany, Canada and Switzerland reduced their presence in the U.S. market by X percentage point each.

Among the importing product categories, the largest shares of imports in the U.S. consumption were held by machining centres for working metal (X% in 2016, based on USD), machine tools, for working metal by forging, hammering etc; machine tools, for working metal by bending, folding, etc; presses for working metaland (X%), lathes, incl. turning centres, for removing metal (X%) and parts and accessories for machine tools for working metal by removing material (X%).

In the medium term, competition with imported machine tools is expected to remain stiff. Besides the strongest competitors from Japan, which traitionally boast high-quality products, some other competitors are to widen their penetration into the US machine tool market. These will be, on the one hand, manufacturers from developing Asian countries, which win clients thanks to their favourable prices, on the other hand, European producers supplying more expensive products but possessing new technological capabilities (for example, increased standards of control and accuracy of processes).

The barriers to entry on the U.S. machine tool market are moderate. The highly fragmented nature of this industry means that product quality and reputation are key to success. The common trend is that metalworking enterprises are concentrated around industrial centers and manufacturers, which encourages a high level of competition at local markets. This trend is spreading both to American and foreign companies. In some areas of this industry, technical knowledge is another common barrier to entry. In this highly competitive U.S. machine tool market, companies with access to the latest and most efficient technologies and those who have business contacts in key consuming markets should secure a sustainable market position.

Do you want to know more about the U.S. machine tool market? Get the latest trends and insight from our report. It includes a wide range of statistics on

- machine tool market share

- machine tool prices

- machine tool industry

- machine tool sales

- machine tool market forecast

- machine tool price forecast

- key machine tool producers

Source: U.S. Machine Tool Market. Analysis And Forecast

This report provides an in-depth analysis of the machine tool market in the U.S.. Within it, you will discover the latest data on market trends and opportunities by country, consumption, production and price developments, as well as the global trade (imports and exports). The forecast exhibits the market prospects through 2030.

Product coverage:

- NAICS 333517 - Machine tool manufacturing

Companies mentioned:

- The Scotts Miracle-Gro Company

- Electroimpact

- Noble Drilling Services

- Trumpf

- Haas Automation

- Gleason Corporation

- Hypertherm

- Victor Technologies Group

- Mazak Corporation

- Hardinge

- Makino Inc.

- Wagstaff

- Atlas Copco Drilling Solutions

- U. S. Tool Grinding

- Wilson Tool International

- Stolle Machinery Company

- Nidec Minster Corporation

- Peddinghaus Corporation

- Kps Capital Partners

- Ridge Tool Company

- Husqvarna Construction Products North America

- Fives Landis Corp.

- Madison Capital Partners

- Graywood Companies

- Schick Manufacturing

- Victor Technologies International

- U.S. Union Tool

- NM Group Global

- Milacron Marketing Company

- Manan Tool & Manufacturing Inc

- Murata Machinery USA Holdings

- Rockwood Service Corporation

- Kobe Steel USA Holdings Inc.

- Victor Technologies Holdings

- Port City Group

Country coverage:

- United States

Data coverage:

- Market volume and value

- Per Capita consumption

- Forecast of the market dynamics in the medium term

- Trade (exports and imports) in the U.S.

- Export and import prices

- Market trends, drivers and restraints

- Key market players and their profiles

Reasons to buy this report:

- Take advantage of the latest data

- Find deeper insights into current market developments

- Discover vital success factors affecting the market

This report is designed for manufacturers, distributors, importers, and wholesalers, as well as for investors, consultants and advisors.

In this report, you can find information that helps you to make informed decisions on the following issues:

- How to diversify your business and benefit from new market opportunities

- How to load your idle production capacity

- How to boost your sales on overseas markets

- How to increase your profit margins

- How to make your supply chain more sustainable

- How to reduce your production and supply chain costs

- How to outsource production to other countries

- How to prepare your business for global expansion

While doing this research, we combine the accumulated expertise of our analysts and the capabilities of artificial intelligence. The AI-based platform, developed by our data scientists, constitutes the key working tool for business analysts, empowering them to discover deep insights and ideas from the marketing data.

-

1. INTRODUCTION

Making Data-Driven Decisions to Grow Your Business

- REPORT DESCRIPTION

- RESEARCH METHODOLOGY AND AI PLATFORM

- DATA-DRIVEN DECISIONS FOR YOUR BUSINESS

- GLOSSARY AND SPECIFIC TERMS

-

2. EXECUTIVE SUMMARY

A Quick Overview of Market Performance

- KEY FINDINGS

- MARKET TRENDS This Chapter is Available Only for the Professional Edition PRO

-

3. MARKET OVERVIEW

Understanding the Current State of The Market and Its Prospects

- MARKET SIZE

- MARKET STRUCTURE

- TRADE BALANCE

- PER CAPITA CONSUMPTION

- MARKET FORECAST TO 2030

-

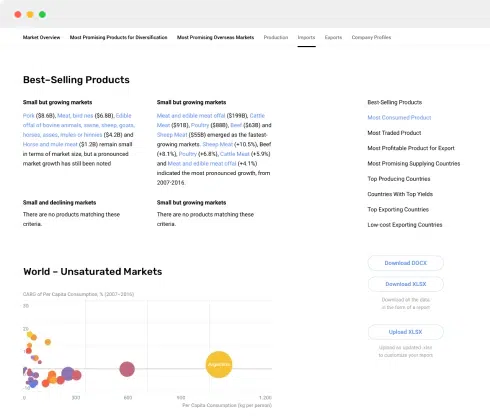

4. MOST PROMISING PRODUCT

Finding New Products to Diversify Your Business

This Chapter is Available Only for the Professional Edition PRO- TOP PRODUCTS TO DIVERSIFY YOUR BUSINESS

- BEST-SELLING PRODUCTS

- MOST CONSUMED PRODUCT

- MOST TRADED PRODUCT

- MOST PROFITABLE PRODUCT FOR EXPORT

-

5. MOST PROMISING SUPPLYING COUNTRIES

Choosing the Best Countries to Establish Your Sustainable Supply Chain

This Chapter is Available Only for the Professional Edition PRO- TOP COUNTRIES TO SOURCE YOUR PRODUCT

- TOP PRODUCING COUNTRIES

- TOP EXPORTING COUNTRIES

- LOW-COST EXPORTING COUNTRIES

-

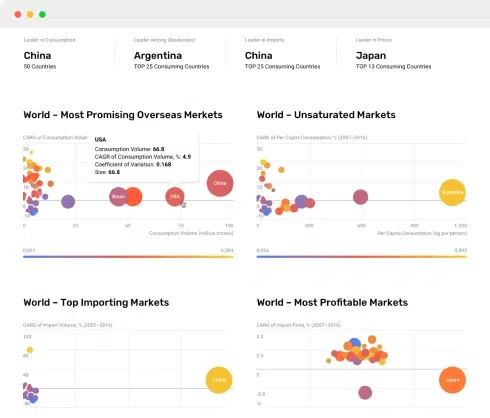

6. MOST PROMISING OVERSEAS MARKETS

Choosing the Best Countries to Boost Your Exports

This Chapter is Available Only for the Professional Edition PRO- TOP OVERSEAS MARKETS FOR EXPORTING YOUR PRODUCT

- TOP CONSUMING MARKETS

- UNSATURATED MARKETS

- TOP IMPORTING MARKETS

- MOST PROFITABLE MARKETS

7. PRODUCTION

The Latest Trends and Insights into The Industry

- PRODUCTION VOLUME AND VALUE

8. IMPORTS

The Largest Import Supplying Countries

- IMPORTS FROM 2012–2023

- IMPORTS BY COUNTRY

- IMPORT PRICES BY COUNTRY

9. EXPORTS

The Largest Destinations for Exports

- EXPORTS FROM 2012–2023

- EXPORTS BY COUNTRY

- EXPORT PRICES BY COUNTRY

-

10. PROFILES OF MAJOR PRODUCERS

The Largest Producers on The Market and Their Profiles

This Chapter is Available Only for the Professional Edition PRO -

LIST OF TABLES

- Key Findings In 2023

- Market Volume, In Physical Terms, 2012–2023

- Market Value, 2012–2023

- Per Capita Consumption In 2012-2023

- Imports, In Physical Terms, By Country, 2012–2023

- Imports, In Value Terms, By Country, 2012–2023

- Import Prices, By Country Of Origin, 2012–2023

- Exports, In Physical Terms, By Country, 2012–2023

- Exports, In Value Terms, By Country, 2012–2023

- Export Prices, By Country Of Destination, 2012–2023

-

LIST OF FIGURES

- Market Volume, In Physical Terms, 2012–2023

- Market Value, 2012–2023

- Market Structure – Domestic Supply vs. Imports, In Physical Terms, 2012-2023

- Market Structure – Domestic Supply vs. Imports, In Value Terms, 2012-2023

- Trade Balance, In Physical Terms, 2012-2023

- Trade Balance, In Value Terms, 2012-2023

- Per Capita Consumption, 2012-2023

- Market Volume Forecast to 2030

- Market Value Forecast to 2030

- Products: Market Size And Growth, By Type

- Products: Average Per Capita Consumption, By Type

- Products: Exports And Growth, By Type

- Products: Export Prices And Growth, By Type

- Production Volume And Growth

- Exports And Growth

- Export Prices And Growth

- Market Size And Growth

- Per Capita Consumption

- Imports And Growth

- Import Prices

- Production, In Physical Terms, 2012–2023

- Production, In Value Terms, 2012–2023

- Imports, In Physical Terms, 2012–2023

- Imports, In Value Terms, 2012–2023

- Imports, In Physical Terms, By Country, 2023

- Imports, In Physical Terms, By Country, 2012–2023

- Imports, In Value Terms, By Country, 2012–2023

- Import Prices, By Country Of Origin, 2012–2023

- Exports, In Physical Terms, 2012–2023

- Exports, In Value Terms, 2012–2023

- Exports, In Physical Terms, By Country, 2023

- Exports, In Physical Terms, By Country, 2012–2023

- Exports, In Value Terms, By Country, 2012–2023

- Export Prices, By Country Of Destination, 2012–2023